shanghai-shundu-automation-equipment-co-ltd

Straightening Press Machine

Custom Straightening Solution For Wide Application: Automotive, Transportation, Oil & Gas, Steel Mills, Precision Machinery, and Several Other Industries.

High Accuracy and Precision:Our plunger servo drive solutions combined with sensitive and synchronously working control systems ensure precise positioning and thus the best reproducible accuracy.

Self-straightening:Our fully automatic systems combine high-precision straightening technology with the advantages of in-house production. These will speed up your process, increase your flexibility and save your money.

The Highlight Of Shundu Straightening Machine

Hydraulic straightening presses are particularly useful for shafts, plates, and large weldments. Machining, heat treatment, and forming can cause these kinds of workpieces to warp or deform. Manufacturers have to remove or reduce such deformation before moving on to the next production steps. Especially for shafts, which are more complicated and have diversified sizes, it is barely possible to automate the straightening process, so a (hydraulic) straightening press is required. Regardless of whether you are bending or straightening large sections of steel alloy I-beams for the railroad industry, high-strength alloys for aerospace parts, or rugged chassis for off-road vehicles, Shundu has the solution.

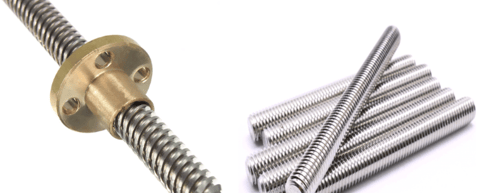

Uses: It is suitable for straightening treatment of screw rods, guide rails, and other products.

Applicable product specifications: 16~63 screw rods, 15~65 guide rails.

Application:

Function:

(1) Equipment straightening adopts hydraulic straightening method.

(2) The straightening feed is controlled by a manual pressure rod and the feed amount is manually controlled according to the dial indicator.

(3) The screw rod and guide rail are equipped with special straightening and fixing fixtures.

Main Configuration And Parameters Of Straightening

|

Number |

Name |

Brand |

|

1 |

Bed body Q235 steel plate |

Baosteel |

|

2 |

hydro-cylinder |

Shundu |

|

3 |

hydraulic pressure system |

Taiwan Youyan |

|

4 |

volume adjustable hydraulic pump |

Taiwan Youyan |

|

5 |

electric motor |

Taiwan Qunce |

|

6 |

electrical equipment |

Schneider |

|

7 |

Mechanical servo valve |

The Origin of Taiwan |

|

8 |

Control electric cabinet |

Shundu |

|

9 |

hydraulic manifold block |

Shundu |

|

10 |

Hydraulic attachment |

Reisle series |

|

11 |

oil pipe |

European Union |

|

12 |

pressure gage |

Shanghai Tianchuan |

|

13 |

LED work light |

Spit |

Company Advantage

We are an OEM factory, we always provide High quality and Fine after-sales, our linear motion guide is manufactured with Precision processing, Pipelining assembly, and 100% QC process. Plentiful stocks, Fast and Safe shipping are our other advantages over other suppliers.

Wholesale

We deliver high-quality and any quantity Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine to our clients worldwide. If you are a Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine distributors, OEM dealers and retailers, feel free to contact us. We welcome big and small orders from you.