shanghai-shundu-automation-equipment-co-ltd

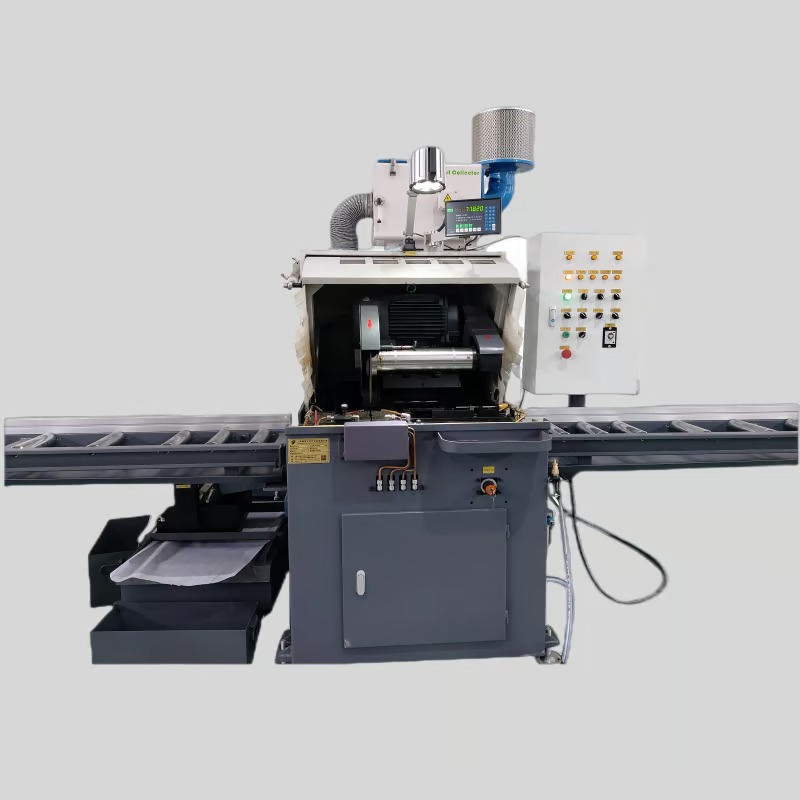

steel bar straightening and cutting machine

MOQ:1 Pcs

Provide OEM & ODM Services

We specialized in manufacturing Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine.

Efficient Steel Bar Straightening and Cutting Machine for Precise Results

Our steel bar straightening and cutting machine is a top-of-the-line equipment designed to streamline the process of straightening and cutting steel bars. With its advanced features and robust construction, this machine offers exceptional performance, accuracy, and efficiency. Whether you're in the construction industry, manufacturing sector, or any other field that requires steel bar processing, our machine is the perfect solution for your needs.

1. Superior Straightening Capability

Equipped with cutting-edge technology, our steel bar straightening and cutting machine ensures precise straightening of steel bars. It effectively removes any bends, twists, or deformities, resulting in perfectly straight bars that meet the highest quality standards. This feature is crucial for various applications where straightness is paramount, such as reinforcement in concrete structures, fabrication of metal components, and more.

2. High Cutting Precision

Accuracy is key when it comes to cutting steel bars, and our machine excels in this aspect. The cutting mechanism is designed to deliver clean and precise cuts with minimal waste. The adjustable cutting length allows you to customize the size of the cut bars according to your specific requirements. Whether you need standard lengths or customized dimensions, our machine ensures consistent and accurate cutting every time.

3. Speed and Efficiency

Time is money, and our steel bar straightening and cutting machine is built to optimize productivity. The powerful motor and efficient mechanisms ensure fast processing of steel bars, reducing downtime and maximizing output. With its high-speed operation, you can handle large volumes of steel bars with ease, enhancing your overall productivity and profitability.

4. User-Friendly Interface

Operating our steel bar straightening and cutting machine is a breeze, thanks to its user-friendly interface. The intuitive controls and clear display allow for easy navigation and monitoring of the machine's functions. Even operators with minimal experience can quickly learn to operate the machine efficiently, minimizing the learning curve and improving overall productivity.

5. Robust Construction for Durability

Investing in a durable and long-lasting machine is essential for any business. Our steel bar straightening and cutting machine is built with high-quality materials and components, ensuring its durability and reliability. The robust construction can withstand heavy-duty usage, making it a reliable asset for years to come. This durability translates into reduced maintenance costs and increased return on investment.

6. Safety Features for Operator Protection

We prioritize the safety of operators, and our machine is equipped with various safety features to prevent accidents and injuries. The machine incorporates emergency stop buttons, safety guards, and other safety mechanisms to ensure a secure working environment. By investing in our steel bar straightening and cutting machine, you can provide your operators with a safe and secure workplace.

7. Versatile Applications

Our steel bar straightening and cutting machine is suitable for a wide range of applications. Whether you're working with mild steel, stainless steel, or other types of steel bars, our machine can handle them all. It is highly versatile and can be used in industries such as construction, manufacturing, metal fabrication, and more. No matter the scale or complexity of your project, our machine is up to the task.

8. Low Maintenance Requirements

Efficiency extends beyond production speed – it also applies to machine maintenance. Our steel bar straightening and cutting machine requires minimal maintenance, thanks to its robust design and high-quality components. Regular inspections and routine maintenance tasks are simple and straightforward, ensuring that your machine remains in optimal condition without significant downtime.

9. Compact Design for Space Optimization

Space is often a constraint in various industries, and our machine is designed with this in mind. Its compact footprint allows you to maximize your workspace without compromising on performance. Whether you have a small workshop or a large manufacturing facility, our steel bar straightening and cutting machine can fit seamlessly into your setup, ensuring efficient utilization of space.

10. Cost-effective Solution

Investing in our steel bar straightening and cutting machine offers long-term cost savings. By automating and streamlining the steel bar processing process, you can eliminate manual labor costs, reduce material waste, and increase overall productivity. The machine's durability and low maintenance requirements further contribute to its cost-effectiveness, making it an excellent investment for your business.

Wholesale

We deliver high-quality and any quantity Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine to our clients worldwide. If you are a Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine distributors, OEM dealers and retailers, feel free to contact us. We welcome big and small orders from you.