shanghai-shundu-automation-equipment-co-ltd

Hydrostatic Guide Rail HLE45-A-XL

Specifications:

Model: Size 15 to 30, standard and lengthened type

Material: Bearing steel

Accuracy Level: N,H

Length of rail : 100mm-4000mm

Hydrostatic Guide Rail HLE45-A-XL

The hydrostatic guideway system is suitable for working conditions that require very high damping, dynamic stiffness and load-carrying capacity.

There is almost no friction between the guide rail and the slider.

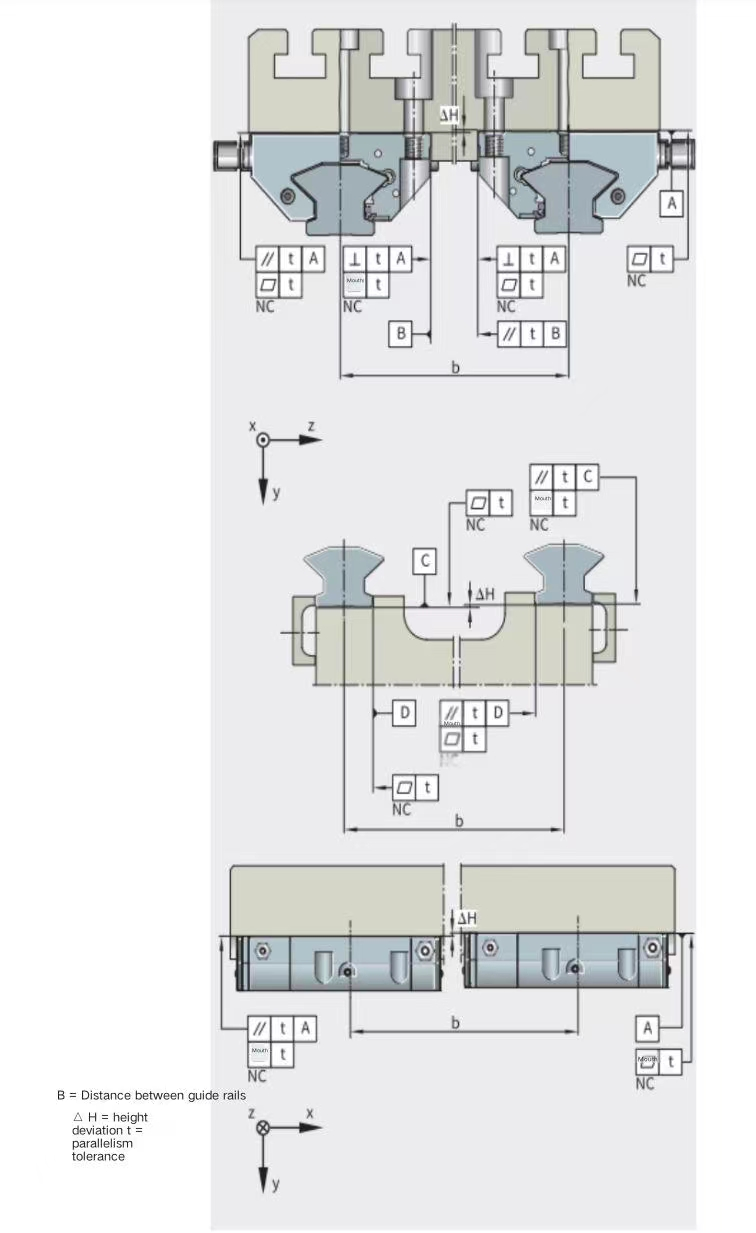

When the hydrostatic guide rail system is used, at least 2 guide rails, each guide rail has 2 sliders; the system with only one guide rail or one slider cannot be used.

Example of order number: 2×HLE45-A-XL-W2-G1

Composition: 2×TSH45-XL-G1/1510-20/202×HLW45-A-SR-XL2×HLW45-A-SL-XL

Sealing: The elastic seals at both ends of the slider and the lower sealing strip protect the system from contamination and prevent the leakage of the hydraulic oil of the slider.

Corrosion Protection: Not designed for corrosion protection.

Characteristic: The bearing oil chamber of the slider is filled with hydraulic oil, and there is pure liquid friction between the slider and the guide rail, which has good lubrication and vibration absorption.

Main purpose:

- High precision machining center

- Heavy duty lathe.

- Gantry machining center

- Horizontal sliding table

- Laser equipment

- Medical equipment

Unique advantages:

- There are lubricating oil chambers inside the slider, both up and down, which can withstand loads from different directions.

- The installation size is the same as that of a regular rolling guidance system, and the frictional resistance hardly changes with the load.

- The rigidity of the pressing direction is equivalent to that of the same type of roller slider.

- Resistant to impact and vibration, can replace the function of damping slider.

Accuracy class: G1.

Applications

Widely used in vertical machining centers, drilling and tapping machines, glass machines, medical equipment, automobile production lines, tire production lines, bottle-blowing machines, palletizing machines, woodworking machinery, etc.

Company Advantage

We are an OEM factory, we always provide High quality and Fine after-sales, our linear motion guide is manufactured with Precision processing, Pipelining assembly, and 100% QC process. Plentiful stocks, Fast and Safe shipping are our other advantages over other suppliers.

Wholesale

We deliver high-quality and any quantity Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine to our clients worldwide. If you are a Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine distributors, OEM dealers and retailers, feel free to contact us. We welcome big and small orders from you.