shanghai-shundu-automation-equipment-co-ltd

Six-row Ball Guide KUSE

Specifications:

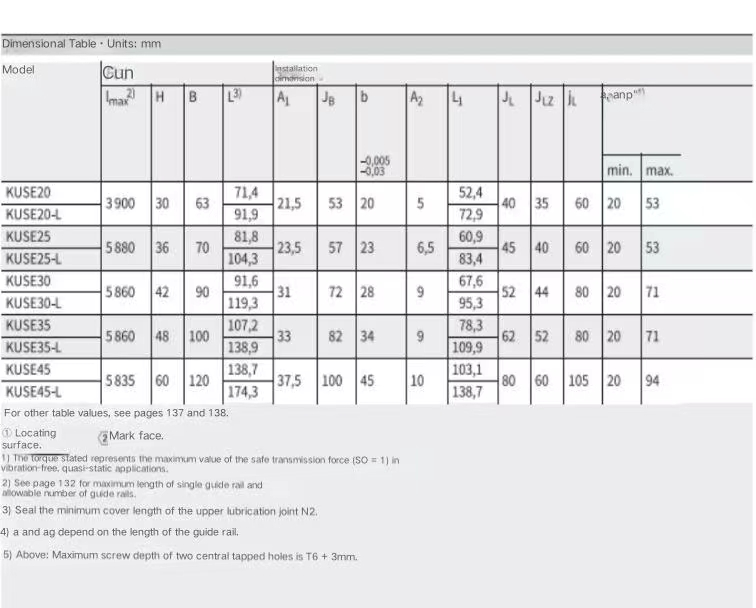

Model: Size 15 to 65, standard and lengthened type

Material: Bearing steel

Accuracy Level: N,H

Length of rail : 100mm-4000mm

Six-row Ball Guide KUSE

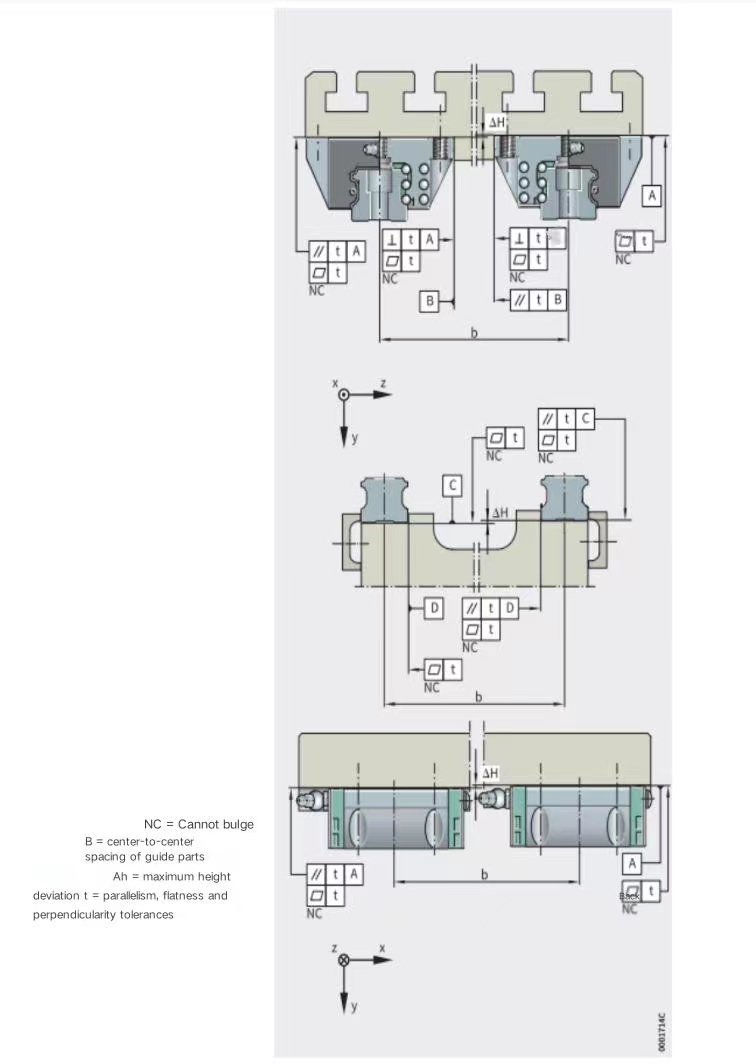

Characteristic: Used for working conditions with unlimited travel, and high or extremely high load rigidity requirements.

Features: The six-row ball guide KUSE is a full-ball system and has been preloaded. It can be used in working conditions with unlimited travel, high or extremely high loads, and high or extremely rigid requirements.

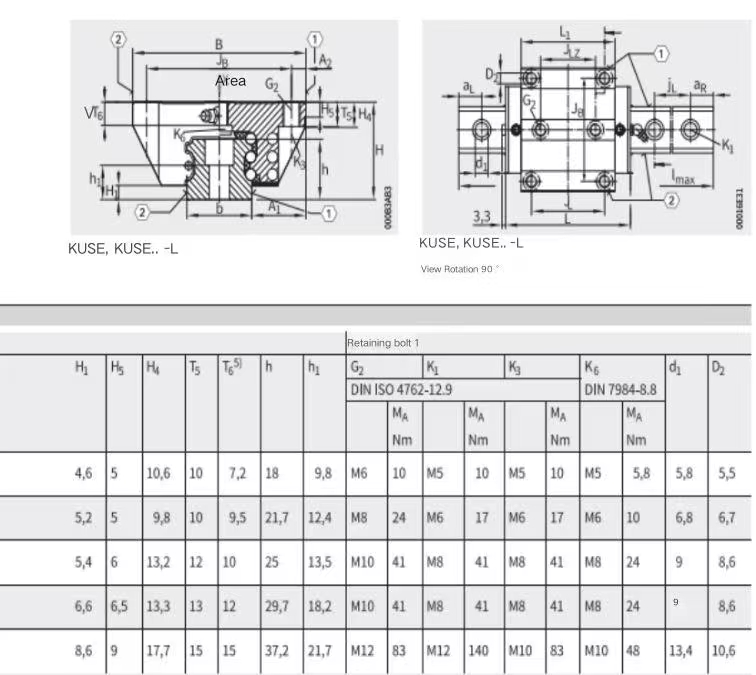

The system consists of at least one full ball runner block, a guide rail, and plastic filler pieces.

The system can be ordered separately for carriage KWSE and guide rail TKSD or as a unit KUSE. In a unit, one or more slides are mounted on a rail.

Lubrication: The six-row ball guide KSUE can be lubricated with oil and grease. If lubricating grease is used, since the slider has a lubricant storage function, it can be maintenance-free in most applications. The lubricant enters the slider from the oil nipple on the end face of the end cover or through the surrounding structure and then through the lubrication hole on the end cover.

Sealing: Effective sealing is guaranteed by standard sealing strips and sealing lips, which protect the rolling elements from contamination under harsh environmental conditions.

Anti-corrosion design:

The six-row ball guide KUSE can also be anti-corrosion coated:

Special coating Corrotect, ProtectA.

Preload grades: V0, V1 and V2, V1 is the standard grade.

Accuracy class: G1 to G4, the standard accuracy class is G3

Application: Used in heavy-duty industries such as large machine tools and gantry.

Main purpose:

- Electrical discharge machining machine

- Wire cutting machine

- Processing center

- Lathe

- Grinder

- Milling machine

Unique advantages:

-

The number of rolling elements increases, and the radial stiffness increases by about 30% compared to the 4-row ball.

-

The radial dynamic rated load is increased by about 100% compared to the 4-column ball.

-

Improving load-bearing capacity without increasing resistance.

Applications

Widely used in vertical machining centers, drilling and tapping machines, glass machines, medical equipment, automobile production lines, tire production lines, bottle-blowing machines, palletizing machines, woodworking machinery, etc.

Company Advantage

We are an OEM factory, we always provide High quality and Fine after-sales, our linear motion guide is manufactured with Precision processing, Pipelining assembly, and 100% QC process. Plentiful stocks, Fast and Safe shipping are our other advantages over other suppliers.

Wholesale

We deliver high-quality and any quantity Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine to our clients worldwide. If you are a Guide ail cutting machine, Automatic packaging line of guide rail and Automaticendgrinder, End grinding roller frame, Cleaning running in machine and Screw running-in machine distributors, OEM dealers and retailers, feel free to contact us. We welcome big and small orders from you.