The frequently asked questions about linear motor technology can vary depending on the context and specific application of linear motors. However, here are some common questions people often have about this technology:

Concept and Operation

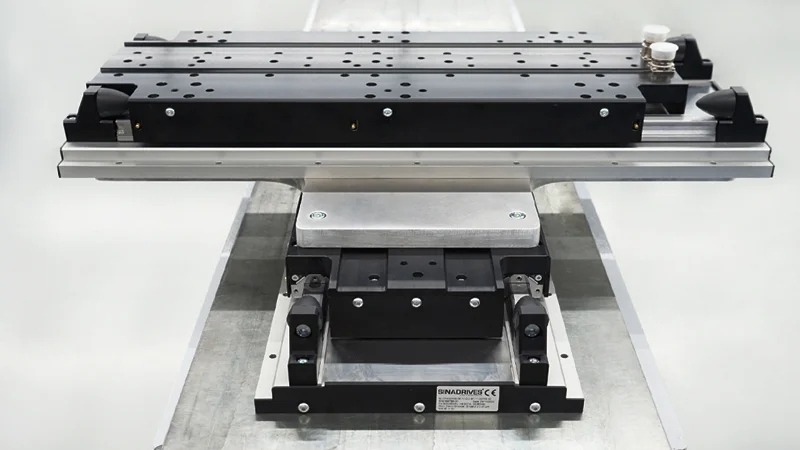

What is a linear motor? A linear motor is a type of electric motor that generates linear motion instead of rotational movement. It uses electromagnetic principles to propel an object along a straight line.

How does a linear motor work? The operation of a linear motor involves the interaction of magnetic fields generated by electric current in coils with a moving element, such as a piston or a slider. The resulting magnetic force drives the linear motion.

What are the applications of linear motors? Linear motors are used in a variety of applications, such as automated transport systems, manufacturing machines, 3D printers, electromagnetic braking systems, and more. Popular sectors include packaging machines, semiconductor machines, testing machines, and printing machines.

Questions and Answers: Advantages and Challenges

What are the advantages of linear motors over rotary motors? Some advantages include increased efficiency in certain scenarios, improved positioning accuracy, faster dynamic response, and the ability to eliminate mechanical components such as gears and belts. Simplification and reduction of the mechanical part reduce the time for design, assembly, adjustment, and commissioning.

What is the difference between a permanent magnet linear motor and a reluctance linear motor? In a permanent magnet linear motor, movement occurs due to the interaction of the magnetic fields from permanent magnets, while in a linear reluctance motor, movement is due to the variation of magnetic reluctance in the path of the magnetic flux.

What are the challenges associated with linear motors? Challenges can include the complexity of the required electronic control and the higher cost for long runs compared to conventional rotary motors.

How do linear motors compare to traditional motors in terms of energy efficiency? In general, linear motors can be more energy-efficient in certain scenarios due to the absence of losses associated with converting rotational movement to linear movement.

Can linear motors be used in high-speed applications? Yes, some linear motors are designed to operate at high speeds, but the feasibility depends on factors such as the specific design of the motor, electronic control, and the application requirements.

Can linear motors be implemented in harsh environments, such as settings with high temperatures or intense vibrations? Yes, certain linear motors are specifically designed to withstand harsh environments, including high temperatures and intense vibrations. The suitability depends on the motor design and the environmental requirements.

Specific Use Cases and Technical Details

What is the importance of the feedback system in linear motors? Feedback is crucial for precise motion control in linear motors. Feedback systems, such as encoders or position sensors, provide real-time information about the position and speed, allowing for more accurate control.

How are speed and position controlled in a linear motor? Speed and position are controlled through electronic systems that adjust the current supplied to the linear motor’s coils. Feedback from sensors helps to fine-tune and maintain the desired position and speed.

Are linear motors suitable for heavy load transport applications? Yes, linear motors are used in heavy load transport systems, such as linear conveyors and lifting systems. The load capacity will depend on the design and specifications of the motor.

Can linear motors be used in low-speed applications? Yes, linear motors can be used in low-speed applications. The speed of a linear motor can be electronically controlled to suit a wide range of speeds, from very low to very high, depending on the specific application and motor design.

Applications where low-speed linear motors can be useful include:

- Precise Positioning Systems: Linear motors can provide smooth and controlled motion at low speeds, making them ideal for precise positioning systems in manufacturing, scientific research, and other areas.

- Low-Speed Conveyors: In conveyor systems where slow and steady movement is required, linear motors can be a suitable choice.

- Medical Devices: In medical applications, such as scanning equipment or dosing systems, linear motors can offer precise movements at low speeds.

- Testing and Experimentation Machines: In laboratory or testing environments where it is crucial to have precise control over the speed of movement, linear motors may be preferred.

Summary

The ability to precisely and variably control speed is one of the advantages of linear motors, making them versatile and adaptable to a wide variety of applications, including those requiring low speeds and precise movements. Linear motors are a valuable space-saving technology, from the automotive industry to aerospace and medical fields, by eliminating bulky mechanical components and improving space efficiency in systems.

If you have any further questions beyond the answered Q&A, we are happy to assist you.