The Basics of pmi ball screw

PMI ball screw is a machine element that converts rotary motion into linear motion, or vice versa. It is comprised of a screw shaft, a ball nut, and a ball return system, which work together to facilitate smooth and precise movement. It is designed to withstand high loads and achieve high accuracy, making it an essential component in a broad range of industrial applications.

The Advantages of PMI Ball Screw

PMI ball screw offers several advantages over other linear motion solutions, such as belt-driven systems or lead screws:

- High efficiency: PMI ball screw can convert up to 90% of input power into linear motion, resulting in lower energy consumption and reduced operating costs.

- High accuracy: PMI ball screw can achieve positioning accuracies as low as 0.005 mm, making it ideal for applications where precision is critical.

- High speed: PMI ball screw can achieve linear speeds of up to 1.5 m/s, making it suitable for high-speed applications.

- Longer service life: PMI ball screw is designed to endure harsh operating environments, resulting in a longer service life.

The Applications of PMI Ball Screw

PMI ball screw can be used in a wide range of industrial applications, including:

- CNC machines: PMI ball screw is commonly used in CNC machines to achieve precise positioning and smooth movement.

- Industrial robotics: PMI ball screw is used in industrial robots to achieve precise and efficient movement of robot arms and end-effectors.

- Medical equipment: PMI ball screw is used in medical equipment, such as imaging systems and surgical robots, to achieve precise and reliable movement.

- Automotive industry: PMI ball screw is used in automotive manufacturing to achieve precise movement of assembly lines and robotic arms.

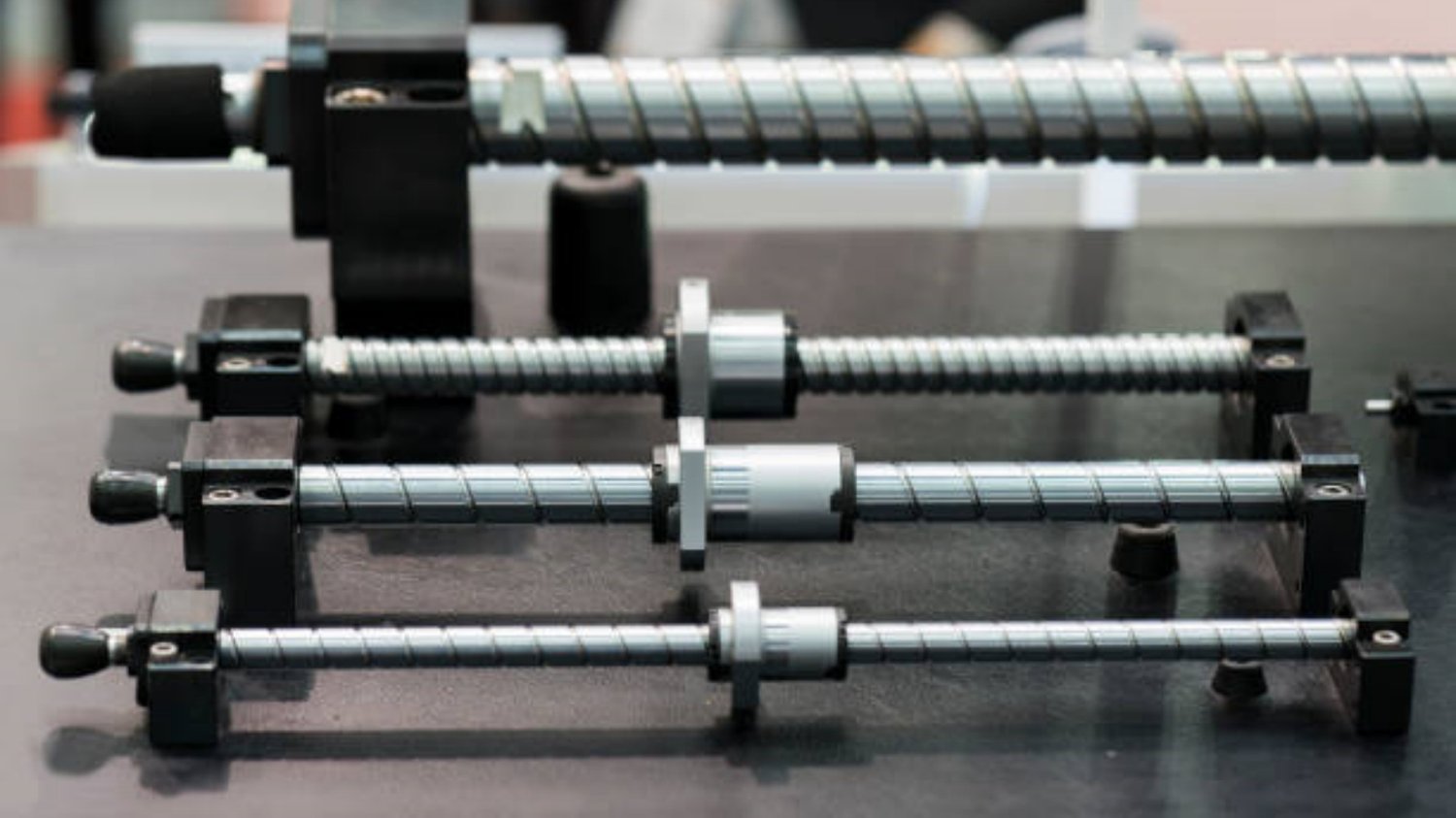

The Components of PMI Ball Screw

PMI ball screw is comprised of three main components:

- Screw shaft: The screw shaft is the main component of the PMI ball screw, and is responsible for the linear movement.

- Ball nut: The ball nut is a housing that contains a series of ball bearings that roll along the helical groove of the screw shaft, converting the rotary motion of the shaft into linear motion.

- Ball return system: The ball return system is responsible for recirculating the ball bearings from the end of the ball nut to the beginning of the helical groove of the screw shaft.

The Types of PMI Ball Screw

PMI ball screw can be classified into three main types, based on the contact angle between the ball bearings and the screw shaft:

- Ground ball screw: Ground ball screw has a contact angle of 90 degrees, which results in high rigidity and high accuracy.

- Rolled ball screw: Rolled ball screw has a contact angle of 45 degrees, which results in lower rigidity and lower accuracy than ground ball screw.

- High-load ball screw: High-load ball screw is designed to withstand high loads, which makes it suitable for heavy-duty applications.

The Maintenance of PMI Ball Screw

PMI ball screw requires regular maintenance to ensure optimal performance and service life. The maintenance tasks include:

- Cleaning: PMI ball screw should be cleaned regularly to remove any dust, dirt, or debris that can interfere with its operation.

- Lubrication: PMI ball screw should be lubricated regularly to reduce friction and wear between the screw shaft and ball nut.

- Inspection: PMI ball screw should be inspected regularly to detect any signs of wear or damage, and to identify any parts that need to be replaced.

The Installation of PMI Ball Screw

PMI ball screw should be installed according to the manufacturer's instructions to ensure optimal performance and safety. The installation tasks include:

- Mounting: PMI ball screw should be mounted securely to prevent any movement or vibration during operation.

- Alignment: PMI ball screw should be aligned properly to ensure smooth and precise movement.

- Lubrication: PMI ball screw should be properly lubricated to ensure smooth and efficient operation.

The Cost of PMI Ball Screw

PMI ball screw can vary in price depending on its size, accuracy, and load capacity. However, the cost of PMI ball screw is generally higher than other linear motion solutions, such as lead screws or belt-driven systems. However, the benefits of PMI ball screw, such as high efficiency, high accuracy, and long service life, often outweigh the initial cost.

The Future of PMI Ball Screw

PMI ball screw is expected to continue to play a critical role in a broad range of industrial applications, due to its high efficiency, high accuracy, and long service life. With advances in technology and manufacturing processes, PMI ball screw is likely to become even more precise, efficient, and reliable in the future.