Introduction

If you're in need of linear motion control solutions for your industrial machinery, pmi ball screws could be the perfect fit. Precision Mechanics Industry (PMI), a Taiwanese company that specializes in manufacturing motion control products, offers a range of high-performance ball screws to meet the needs of various industries. But what exactly is a PMI ball screw and what makes it unique? This article will explore everything you need to know about PMI ball screws.

What is a PMI Ball Screw?

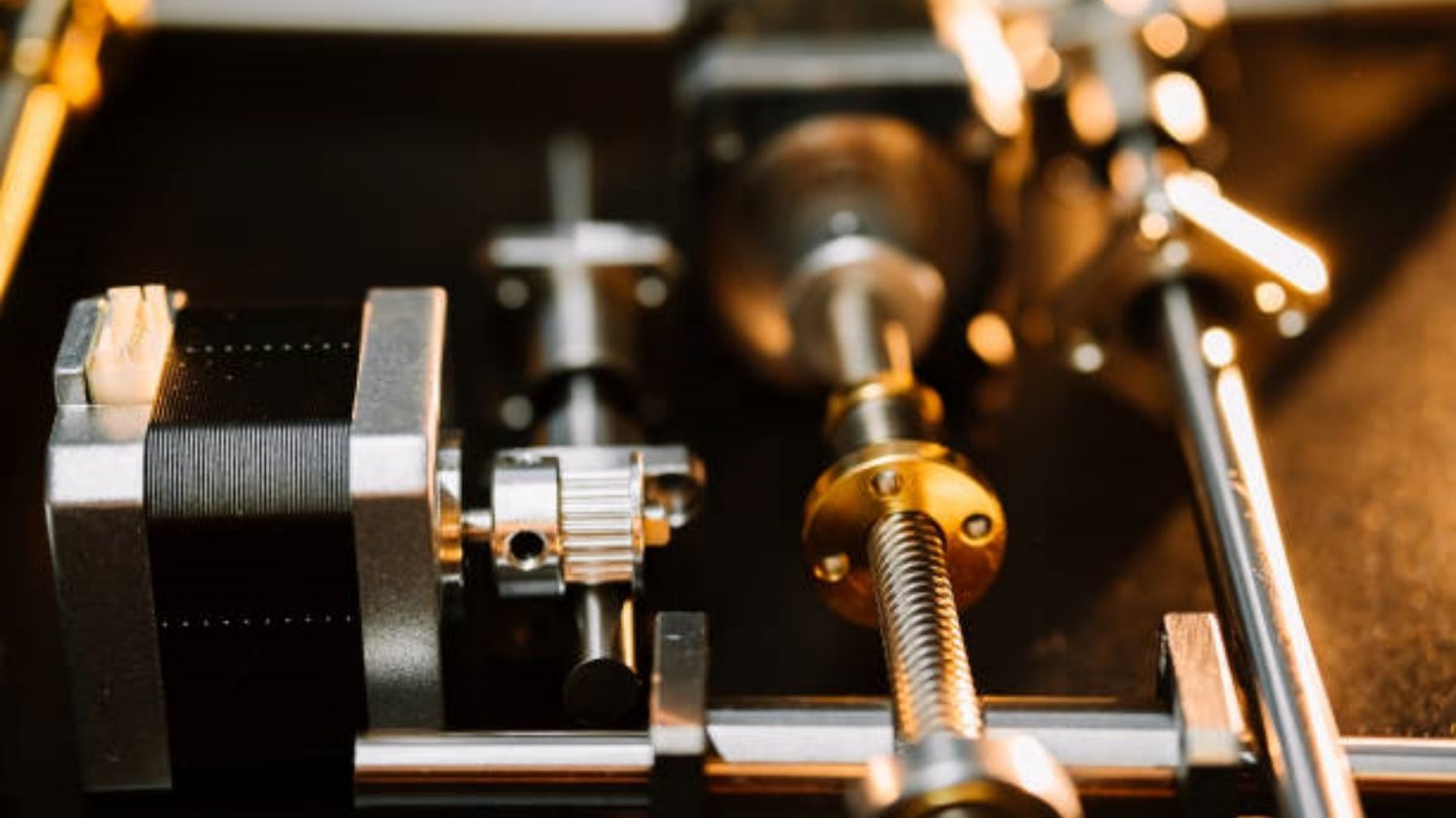

A PMI ball screw is a type of linear motion control component used to convert rotary motion to linear motion and vice versa. The screw shaft consists of a precision ground thread and a series of ball bearings that roll between the screw shaft and the nut. This mechanism enables smooth and efficient linear motion with high accuracy, repeatability, and rigidity. PMI ball screws are commonly used in industrial machinery such as CNC machines, aerospace equipment, medical equipment, and semiconductor equipment.

PMI Ball Screw Advantages

There are several advantages to using PMI ball screws in your industrial machinery. First, they can handle heavy loads with high precision and efficiency. Second, they have a long service life and low maintenance requirements, which can save you time and money. Third, they have a high degree of rigidity and can withstand vibration and shock without compromising accuracy. Finally, PMI ball screws come in a range of sizes and configurations to fit your specific application requirements.

PMI Ball Screw Components

A PMI ball screw is composed of several key components, including:

- Screw Shaft - The screw shaft is the central component of the ball screw and is responsible for rotating to generate linear motion.

- Nut - The nut is attached to the linear moving component and houses the ball bearings that roll along the screw shaft to enable linear motion.

- Balls - The balls are the rolling elements that enable the smooth and efficient linear motion of the nut along the screw shaft.

- End Support Units - End support units are used to support the screw shaft at the ends and prevent deflection and misalignment.

PMI Ball Screw Configurations

PMI ball screws come in various configurations to meet different application requirements:

- Precision Ground Ball Screws - These ball screws are manufactured according to JIS standards and have precision-ground balls and threads for high accuracy and rigidity.

- Cold Rolled Ball Screws - These ball screws have a cold-rolled thread profile and are designed for low to moderate accuracy applications.

- High-Speed Ball Screws - These ball screws are specially designed for high-speed applications and feature a high helix angle for increased efficiency.

- Miniature Ball Screws - These ball screws are designed for small and lightweight applications where space is limited.

PMI Ball Screw Selection Criteria

When selecting a PMI ball screw for your application, it's important to consider several factors, including:

- Load capacity and direction

- Speed and acceleration requirements

- Precision and repeatability

- Environmental conditions

- Mounting options and space limitations

- Budget constraints

PMI Ball Screw Installation and Maintenance

Proper installation and maintenance can extend the service life and performance of your PMI ball screw. Always follow the manufacturer's instructions for installation and use. Regular maintenance, including lubrication and cleaning, can prevent wear and damage to the ball screw components. If you notice any signs of wear or abnormal noise or vibration, it's important to address the issue promptly to avoid further damage.

PMI Ball Screw Applications

PMI ball screws are used in a wide range of industrial applications, including:

- CNC machines

- Robotic arms

- Aerospace equipment

- Medical equipment

- Semiconductor equipment

Where to Buy PMI Ball Screws?

If you're interested in purchasing PMI ball screws for your machinery, you can contact a local distributor or authorized dealer. Online retailers such as Amazon and Alibaba also carry a range of PMI ball screws.

Conclusion

PMI ball screws offer a reliable and efficient solution for linear motion control in various industrial applications. The key advantages of PMI ball screws include high precision, efficiency, rigidity, and durability. With a range of sizes and configurations available, PMI ball screws can be tailored to meet the specific needs of your application. When selecting and using PMI ball screws, it's important to follow manufacturer's instructions and consider factors such as load capacity, speed requirements, and maintenance.