Several types of cutting machines are suitable for cutting linear guides, each with its own advantages depending on the specific requirements of the task. Here are some common types:

-

Band Saws:

- Advantages: Band saws are versatile and can handle various materials and thicknesses. They are ideal for making straight cuts and can be used for both small-scale and large-scale operations.

- Applications: Suitable for cutting longer linear guides into desired lengths with precision.

-

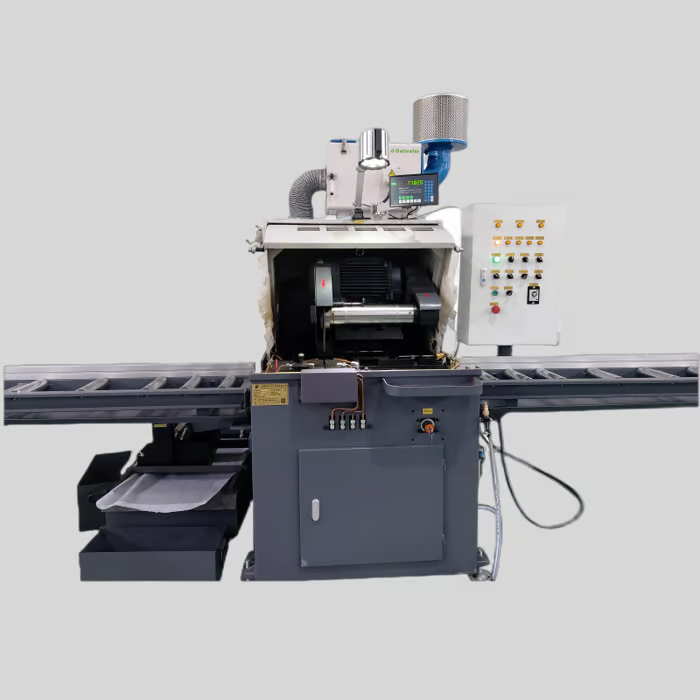

- Advantages: Circular saws provide fast and efficient cutting with clean edges. They are often used for high-volume production due to their speed and accuracy.

- Applications: Ideal for cutting linear guides in mass production environments.

-

CNC Machines:

- Advantages: CNC (Computer Numerical Control) machines offer the highest precision and repeatability. They can be programmed for complex cutting patterns and ensure consistent quality.

- Applications: Used in high-precision industries where exact dimensions and tight tolerances are crucial, such as aerospace and automotive manufacturing.

-

Miter Saws:

- Advantages: Miter saws allow for angled cuts and are useful for creating precise joints and edges. They are relatively easy to use and can be adjusted for various angles.

- Applications: Often used for custom cutting of linear guides where specific angles are required.

-

Laser Cutting Machines:

- Advantages: Laser cutting machines provide extremely precise cuts with a clean finish. They are suitable for intricate cutting and can handle a wide range of materials.

- Applications: Ideal for cutting complex shapes or designs in linear guides, particularly in industries requiring high precision and minimal material waste.

-

Plasma Cutting Machines:

- Advantages: Plasma cutters are effective for cutting thick and tough materials quickly. They offer good precision and can cut through various metals.

- Applications: Suitable for heavy-duty cutting tasks where speed and efficiency are prioritized.

-

Water Jet Cutting Machines:

- Advantages: Water jet cutters use a high-pressure stream of water mixed with abrasive materials to cut through various substances. They do not generate heat, which prevents material deformation.

- Applications: Ideal for cutting linear guides made of materials sensitive to heat, such as certain alloys and composites.

Each type of cutting machine offers distinct benefits, and the choice depends on factors such as material type, required precision, production volume, and specific cutting needs.