Cutting machines suitable for cutting linear guides typically need to meet certain criteria to ensure precision, efficiency, and safety. Here are the types commonly used:

-

Abrasive Waterjet Cutting Machines:

- Abrasive waterjet cutting machines use a high-pressure jet of water mixed with abrasive particles to cut through materials like hardened steel, aluminum, or other metals used in linear guides. They offer precise cuts without creating heat-affected zones, which can be critical for maintaining material integrity.

-

Laser Cutting Machines:

- Laser cutting machines utilize a focused laser beam to cut through various materials, including metals like stainless steel and aluminum. They provide high precision and can handle complex shapes and intricate patterns, making them suitable for cutting linear guides with tight tolerances.

-

Plasma Cutting Machines:

- Plasma cutting machines use ionized gas to cut through electrically conductive materials such as steel, stainless steel, and aluminum. They are capable of cutting thick materials quickly and are suitable for industrial applications where linear guides are manufactured in bulk.

-

CNC (Computer Numerical Control) Cutting Machines:

- CNC cutting machines encompass various types such as CNC routers, CNC plasma cutters, and CNC laser cutters. These machines are controlled by computer programs that dictate the cutting path, allowing for precise and repeatable cuts in materials used for linear guides.

-

Band Saws:

- Band saws equipped with specialized blades can be used for cutting linear guide rails made from aluminum or softer metals. They are suitable for cutting straight lines and can be configured with guides and fixtures to ensure accuracy and consistency.

-

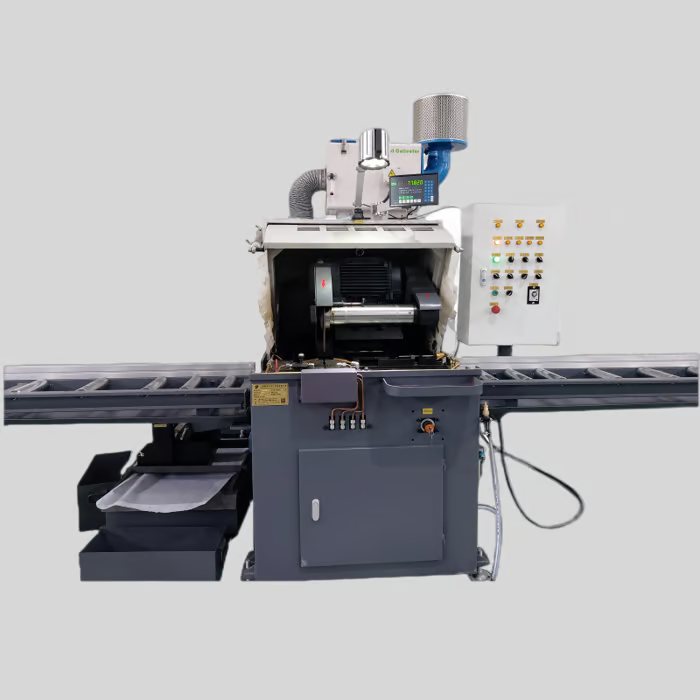

Circular Cold Saws:

- Circular cold saws are designed for cutting solid steel bars and tubes used in linear guides. They operate at lower speeds than conventional circular saws, minimizing heat buildup and preventing material deformation or hardening, which is crucial for maintaining the dimensional accuracy of linear guide components.

-

Shearing Machines:

- Shearing machines are used for cutting sheet metal and thin plates typically used in linear guide components such as brackets and mounting plates. They provide straight cuts and are suitable for high-volume production environments.

When selecting a cutting machine for linear guides, considerations such as the material type, thickness, required precision, production volume, and operational costs should be taken into account to ensure optimal performance and efficiency in manufacturing processes.