An auto chamfering machine for guide rails is a specialized type of chamfering machine designed to automatically bevel the edges of guide rails. Guide rails are components used in various mechanical systems, such as linear motion systems, to guide and support moving parts. The primary functions of an auto chamfering machine for guide rails include:

- Edge Beveling: Creating a chamfered edge on the guide rail to remove sharp edges, which improves safety and handling.

- Surface Preparation: Preparing the guide rail edges for further processing, such as coating or assembly.

- Precision and Consistency: Ensuring that the chamfering is performed with high precision and uniformity across multiple guide rails, which is critical for the proper functioning of linear motion systems.

- Efficiency: Automating the chamfering process to increase production speed and reduce manual labor.

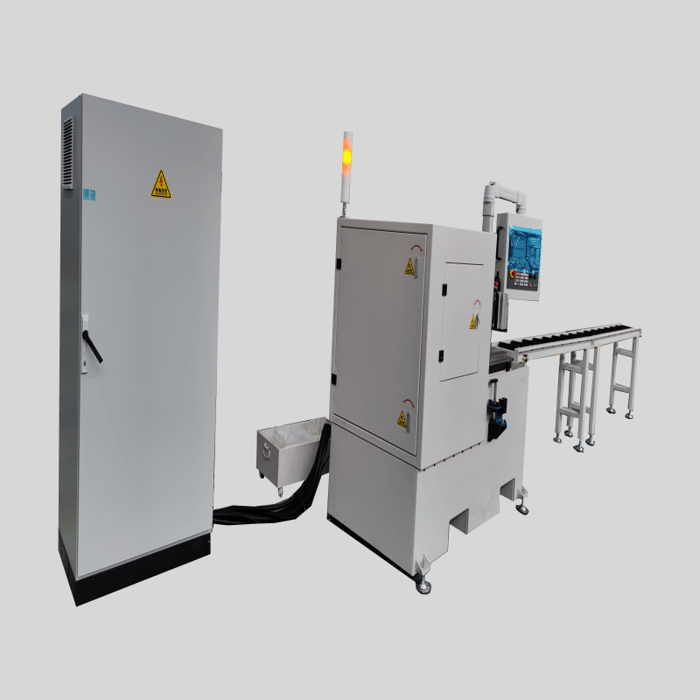

These machines typically feature automated feeding systems, precision cutting tools, and control systems that allow for consistent and repeatable chamfering operations. They are used in industries such as automotive, aerospace, and manufacturing, where guide rails are essential components.