Introduction: Understanding the Importance of automatic straightening machines

Automatic straightening machines play a crucial role in various industries, enabling precision and efficiency in straightening metal components. These machines are designed to correct deformations and imperfections in metal parts, ensuring they meet the required standards for quality and functionality. In this comprehensive guide, we will delve into the world of automatic straightening machines, exploring their benefits, applications, and the key factors to consider when investing in one.

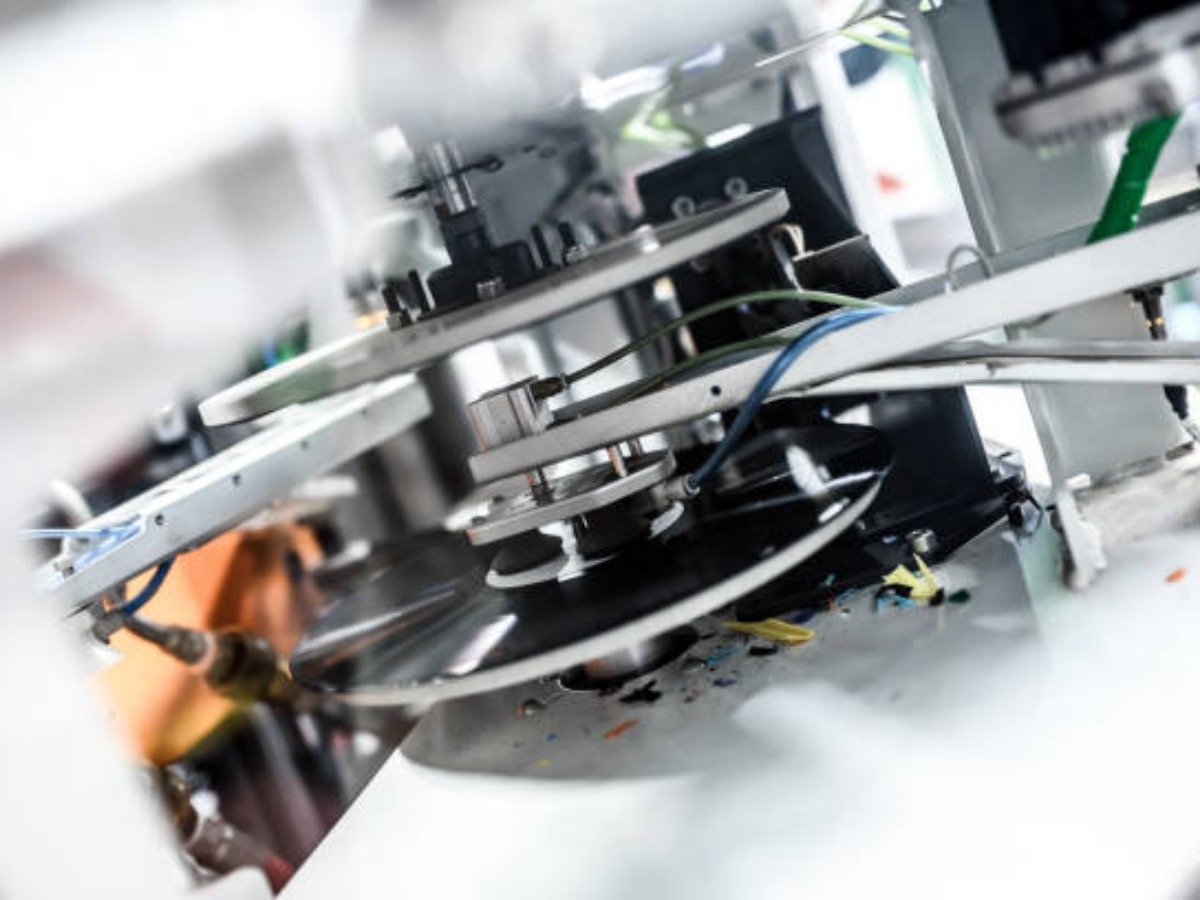

1. What is an Automatic Straightening Machine?

An automatic straightening machine is a specialized equipment used to straighten metal components, such as rods, bars, tubes, and shafts. It employs a combination of hydraulic, mechanical, or pneumatic forces to reshape the material and remove any distortions or bends. These machines utilize innovative technologies, including computer numerical control (CNC), to precisely adjust the straightening process, ensuring consistent results.

2. The Advantages of Using Automatic Straightening Machines

Automatic straightening machines offer numerous advantages over manual straightening methods. Firstly, they provide higher productivity and efficiency, as they can process a large number of parts in a shorter time. This leads to significant time and cost savings for manufacturers. Additionally, these machines deliver exceptional precision, ensuring consistent straightness and dimensional accuracy. They also reduce the risk of human error and injuries associated with manual straightening methods.

3. Applications of Automatic Straightening Machines

Automatic straightening machines find applications in various industries, including automotive, aerospace, construction, and manufacturing. They are commonly used to straighten components such as crankshafts, axles, drive shafts, and precision tubes. These machines are essential in the production of high-quality components, ensuring that they meet the strict requirements of their respective industries.

4. Factors to Consider When Choosing an Automatic Straightening Machine

When investing in an automatic straightening machine, several factors should be taken into consideration. Firstly, the machine's capacity and capabilities must align with the specific needs of your production line. It is essential to consider the maximum length, diameter, and weight of the components you intend to straighten. Additionally, the machine's straightening force, speed, and precision should be evaluated to ensure it can meet your quality standards.

5. Key Features to Look for in an Automatic Straightening Machine

To make an informed decision, it is crucial to assess the key features of automatic straightening machines. Look for machines with advanced control systems, such as CNC, which allow for precise adjustments and repeatability. Consider machines with automatic feeding and unloading mechanisms to optimize workflow and minimize manual labor. Furthermore, a user-friendly interface and intuitive programming options can significantly enhance operational efficiency.

6. Maintenance and Safety Considerations

Regular maintenance is essential to ensure the optimal performance and longevity of automatic straightening machines. Follow manufacturer guidelines for routine inspections, lubrication, and calibration. It is also important to implement safety measures, such as installing emergency stop buttons and guards, to protect operators and prevent accidents. Training operators on proper machine operation and safety protocols is equally crucial.

7. Common Challenges and Troubleshooting

Despite their efficiency, automatic straightening machines may encounter certain challenges. One common issue is material springback, where the component returns to its original shape after the straightening process. This can be mitigated by adjusting the straightening force or employing specialized techniques. Other challenges may include misalignment, vibration, or excessive noise, which can be resolved through proper machine setup and maintenance.

8. The Future of Automatic Straightening Machines

As technology continues to advance, automatic straightening machines are expected to become even more sophisticated. Industry 4.0 concepts, such as machine learning and artificial intelligence, may be integrated into these machines, enabling them to adapt and optimize the straightening process based on real-time data. This will further enhance productivity, accuracy, and overall efficiency in metal component manufacturing.

9. Conclusion

Automatic straightening machines revolutionize the metalworking industry by providing a reliable and efficient solution for correcting deformations in metal components. With their precision, productivity, and versatility, these machines have become indispensable in various sectors. By considering the factors mentioned in this guide, you can make an informed decision when selecting an automatic straightening machine that meets your specific requirements.

10. Related Long-tail SEO Keywords

- Precision automatic straightening machine - High-speed automatic straightening machine - CNC automatic straightening machine - Hydraulic automatic straightening machine - Pneumatic automatic straightening machine - Industrial automatic straightening machine - Automatic straightening machine for crankshafts - Automatic straightening machine for precision tubes - Automated metal straightening machine - Robotic automatic straightening machine