Enhancing Precision and Durability: heavy duty linear guide rails

When it comes to industrial applications that require smooth and precise linear motion, heavy duty linear guide rails are an essential component. These robust and reliable mechanisms play a critical role in various industries, ensuring the smooth movement of heavy loads with utmost accuracy. In this article, we will explore the benefits and applications of heavy duty linear guide rails, shedding light on why they are the preferred choice for many industrial processes.

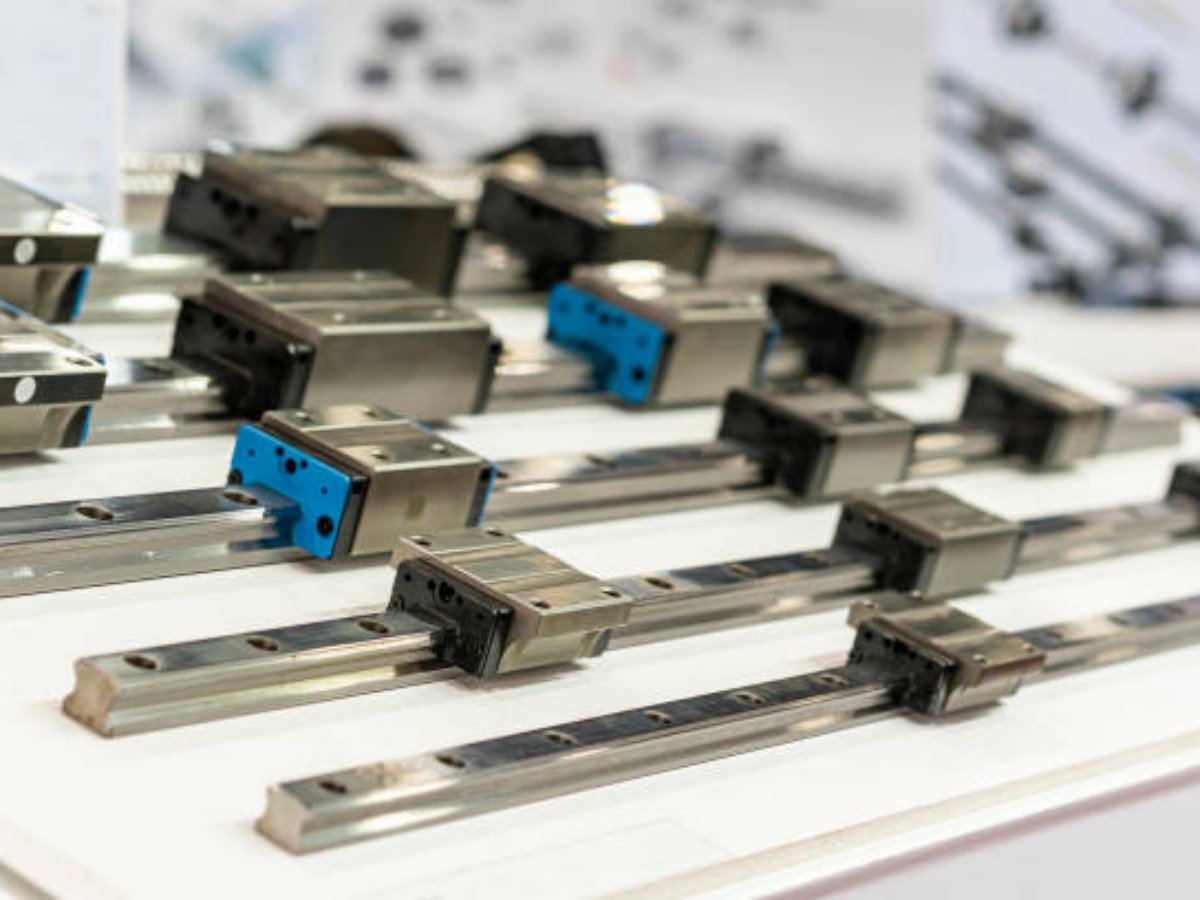

1. What Are Heavy Duty Linear Guide Rails?

Heavy duty linear guide rails, also known as linear motion guides or linear slides, are mechanical systems designed to facilitate smooth and controlled linear motion. They consist of a rail and a carriage, where the carriage is mounted on the rail, enabling the movement of heavy loads in a straight line. These guide rails typically employ rolling elements, such as balls or rollers, to reduce friction and enhance the motion efficiency.

2. The Importance of Precision in Industrial Applications

Precision is of utmost importance in many industrial applications, such as manufacturing, automation, robotics, and heavy machinery. Heavy duty linear guide rails play a crucial role in ensuring the high level of precision required for these processes. With their ability to provide smooth and accurate linear motion, these guide rails contribute to the overall quality and efficiency of industrial operations.

3. Advantages of Heavy Duty Linear Guide Rails

Heavy duty linear guide rails offer numerous advantages over other linear motion systems. Let's delve into some of the key benefits:

3.1 High Load Capacity

Unlike traditional linear motion systems, heavy duty linear guide rails have a significantly higher load capacity. They are designed to handle heavy loads, making them ideal for applications where large and heavy objects need to be moved with precision.

3.2 Rigidity and Stability

One of the main advantages of heavy duty linear guide rails is their exceptional rigidity and stability. The rail and carriage structure ensures minimal deflection, even under heavy loads and high-speed movements. This rigidity helps maintain the precise positioning of the load, preventing any deviations or inaccuracies.

3.3 Smooth and Quiet Operation

With their rolling elements and high-quality design, heavy duty linear guide rails offer smooth and quiet operation. The reduced friction and optimized motion control result in minimal noise generation, making them suitable for applications where noise reduction is essential.

3.4 Longevity and Reliability

Heavy duty linear guide rails are built to withstand the demanding conditions of industrial environments. They are constructed from durable materials, such as stainless steel or hardened steel, ensuring longevity and reliability even in harsh operating conditions.

3.5 Easy Installation and Maintenance

Installing and maintaining heavy duty linear guide rails is relatively straightforward. These systems are designed for easy installation, with various mounting options available. Additionally, regular maintenance tasks, such as lubrication and cleaning, can be performed efficiently, minimizing downtime and ensuring optimal performance.

4. Applications of Heavy Duty Linear Guide Rails

Heavy duty linear guide rails find applications in a wide range of industries and processes. Here are some notable examples:

4.1 CNC Machining

In computer numerical control (CNC) machining, heavy duty linear guide rails enable precise movement of the cutting tool or workpiece, ensuring accurate shaping and machining operations.

4.2 Material Handling

Heavy duty linear guide rails are commonly used in material handling systems, facilitating the smooth and controlled movement of heavy loads in warehouses, manufacturing plants, and logistics operations.

4.3 Robotics and Automation

Industrial robots and automated systems rely on heavy duty linear guide rails to achieve precise and repeatable linear motion. These guide rails enable robots to perform tasks with high accuracy and efficiency.

4.4 Medical and Laboratory Equipment

From surgical robots to laboratory automation, heavy duty linear guide rails are extensively used in medical and laboratory equipment to ensure precise positioning and movement of sensitive instruments and samples.

4.5 Packaging and Printing

In packaging and printing industries, heavy duty linear guide rails facilitate the smooth operation of machines involved in packaging, labeling, and printing processes, ensuring precise positioning and alignment.

5. Conclusion

Heavy duty linear guide rails are essential components in various industrial applications that demand precise and smooth linear motion. With their high load capacity, rigidity, stability, and longevity, these guide rails offer numerous advantages over other linear motion systems. Whether in CNC machining, material handling, robotics, medical equipment, or packaging, heavy duty linear guide rails play a vital role in enhancing the efficiency and accuracy of industrial processes.