Introduction

In the realm of precision motion control, the seamless collaboration between a linear guide rail and carriage system plays a pivotal role. This dynamic duo forms the backbone of numerous machines and systems across industries, enabling smooth and accurate linear motion. In this article, we will delve into the intricacies of linear guide rail and carriage systems, exploring their components, advantages, versatile applications, installation considerations, and essential maintenance practices. Join us as we unlock the secrets behind their exceptional precision and reliability.

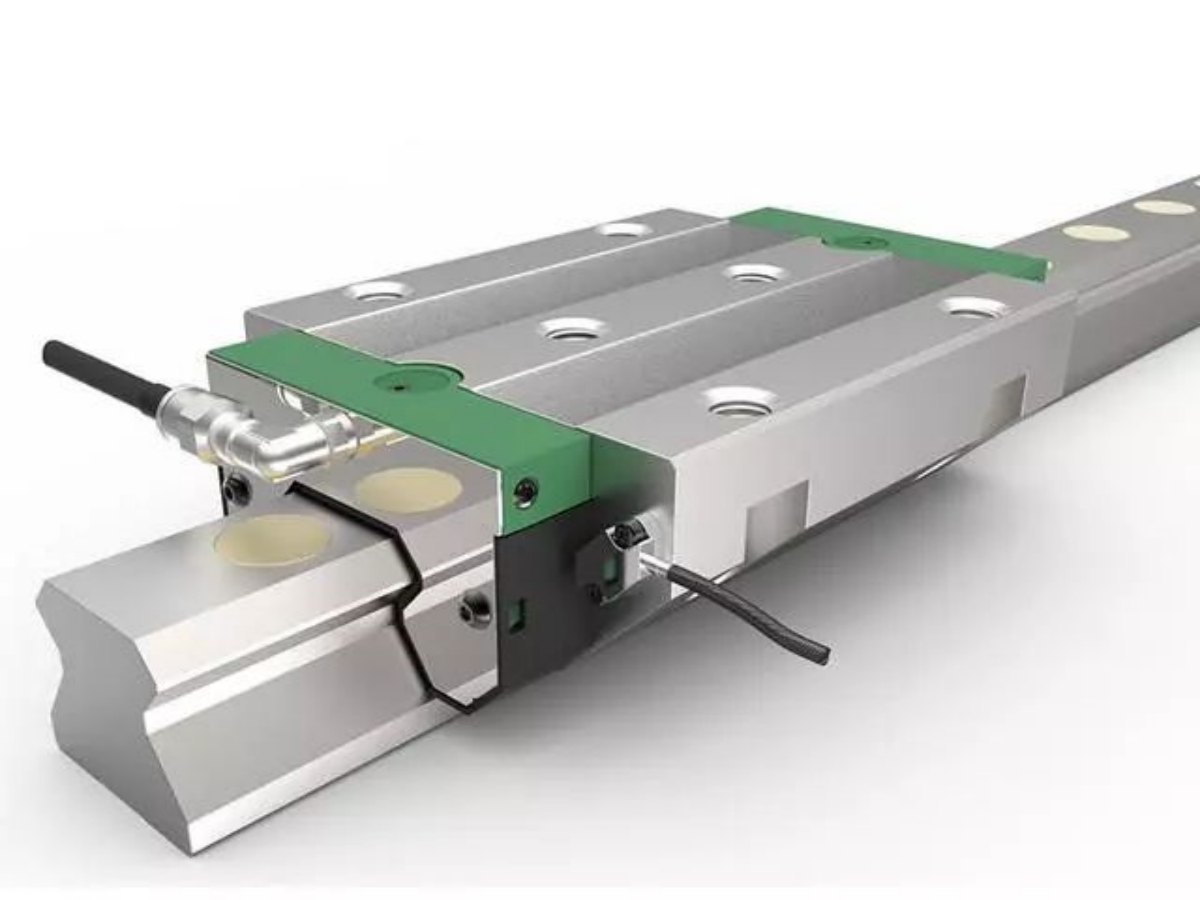

Components of a Linear Guide Rail and Carriage System

At the core of a linear guide rail and carriage system lies the linear guide rail, a carefully engineered structure that provides a rigid and precise path for linear motion. These guide rails are available in various types, such as profiled rails or round rails, and are designed to accommodate different load and motion requirements. Accompanying the guide rail is the carriage, which houses the rolling elements that facilitate smooth movement along the rail. Carriages come in different types, including plain bearings or ball bearings, each offering specific features and benefits.

Advantages of Linear Guide Rail and Carriage Systems

Linear guide rail and carriage systems bring forth an array of advantages. Their precise and smooth linear motion ensures accuracy in positioning and reliable performance. These systems exhibit high load-bearing capacities, allowing them to handle heavy loads with ease. The low friction design minimizes wear and tear, leading to extended operational lifespans. Moreover, the integration of carriages with other mechanical systems enhances stability and rigidity, ensuring consistent performance in demanding applications. Installation and maintenance of linear guide rail and carriage systems are relatively straightforward, making them accessible and user-friendly.

Applications of Linear Guide Rail and Carriage Systems

The versatility of linear guide rail and carriage systems enables their application in various industries. In industrial machinery and automation, they play a crucial role in CNC machines, robotic systems, and assembly lines, ensuring precise and repeatable movements. The medical and laboratory fields rely on these systems for accurate positioning in scanning devices and laboratory automation. In semiconductor and electronics manufacturing, linear guide rail and carriage systems facilitate precise wafer handling and inspection processes. Printing and packaging industries benefit from their smooth and controlled movements in printers, plotters, and packaging machines.

Selection and Installation Considerations

When selecting and installing linear guide rail and carriage systems, several factors must be taken into account. Load and speed requirements dictate the choice of rail and carriage types to ensure optimal performance. Environmental factors like temperature and dust levels influence the selection of materials and protective measures. Proper mounting and alignment guidelines should be followed to guarantee smooth and accurate linear motion.

Maintenance and Care for Linear Guide Rail and Carriage Systems

To ensure long-lasting and optimal performance, regular maintenance of linear guide rail and carriage systems is essential. Routine cleaning and lubrication help minimize friction and prevent premature wear. Regular inspections should be conducted to identify any signs of wear or damage and take timely corrective measures. Replacement of worn-out components is crucial to maintaining the system's performance and accuracy.

Conclusion

Linear guide rail and carriage systems are the driving force behind precise linear motion in various industries. Their versatility, accuracy, and reliability make them indispensable components in countless applications. By understanding their components, advantages, installation considerations, and maintenance practices, users can harness the full potential of these systems and achieve optimal performance in their respective fields.