In linear motion systems, linear guides and linear rods serve distinct functions and are used in different types of applications. Understanding their differences is crucial for selecting the right component for your needs.

Linear Guides

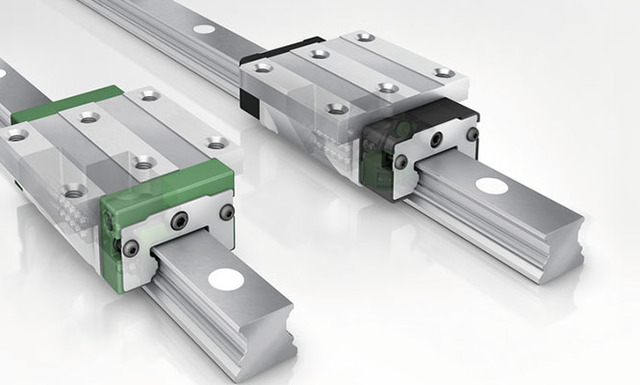

Linear guides (also known as linear rails or linear slides) are precision components designed to provide smooth and accurate linear motion along a predefined path. They consist of two main parts:

- Rail: A stationary track that is fixed to the mounting surface.

- Carriage: A moving component that slides along the rail, supporting the load and ensuring precise movement.

Key Characteristics of Linear Guides:

- Precision: Linear guides are engineered for high precision and accuracy. They offer excellent repeatability and are used in applications where exact positioning is required.

- Load Capacity: They can handle significant loads and are suitable for heavy-duty applications. The design allows for even distribution of forces, reducing wear and increasing durability.

- Rigidity: The rigid design of linear guides provides stability and minimizes deflection, which is essential for applications requiring high rigidity.

- Enclosed Design: Many linear guides feature an enclosed design that protects against contaminants, dust, and debris, extending their service life.

Typical Applications:

- CNC machines

- Robotics

- Measurement devices

- Semiconductor manufacturing equipment

Linear Rods

Linear rods (also known as shafts or linear shafts) are simple cylindrical components used as a track or guide for linear motion. They are typically mounted in a fixed position and serve as the surface along which a linear bearing or other moving part travels.

Key Characteristics of Linear Rods:

- Simplicity: Linear rods are relatively simple and consist of a straight cylindrical shaft. They are less complex than linear guides and generally easier to install.

- Cost: Linear rods are typically less expensive than linear guides, making them a cost-effective solution for applications with less demanding requirements.

- Versatility: They can be used with various types of linear bearings (such as ball bearings or plain bearings) to create a linear motion system. Linear rods are available in different materials and diameters to suit various needs.

- Load Capacity: Linear rods can support moderate loads but may not be suitable for very heavy or high-precision applications.

Typical Applications:

- Home and office equipment

- Simple linear motion systems

- Light-duty automation

- Basic machinery and conveyors

Comparison and Selection

When deciding between linear guides and linear rods, consider the following factors:

-

Precision and Accuracy:

- Linear Guides: Best for applications requiring high precision and accuracy.

- Linear Rods: Suitable for applications where precision is less critical.

-

Load Capacity:

- Linear Guides: Capable of handling heavier loads and providing better support.

- Linear Rods: Suitable for moderate loads; less capable of handling very heavy loads.

-

Cost:

- Linear Guides: Generally more expensive due to their precision and load-bearing capabilities.

- Linear Rods: More cost-effective, ideal for budget-conscious projects.

-

Environmental Protection:

- Linear Guides: Often feature an enclosed design for better protection against contaminants.

- Linear Rods: May require additional measures for protection against dust and debris.

-

Complexity and Installation:

- Linear Guides: More complex, requiring precise alignment and installation.

- Linear Rods: Simpler to install, often used in less demanding applications.

By evaluating these factors, you can choose the component that best fits your specific application, ensuring efficient and reliable linear motion in your system.