When it comes to choosing the right linear guide rail system for your industrial or commercial application, there are several factors to consider. The performance, durability, and precision of the system play a crucial role in determining the overall efficiency and productivity of your operations.

Understanding Linear Guide Rail Systems

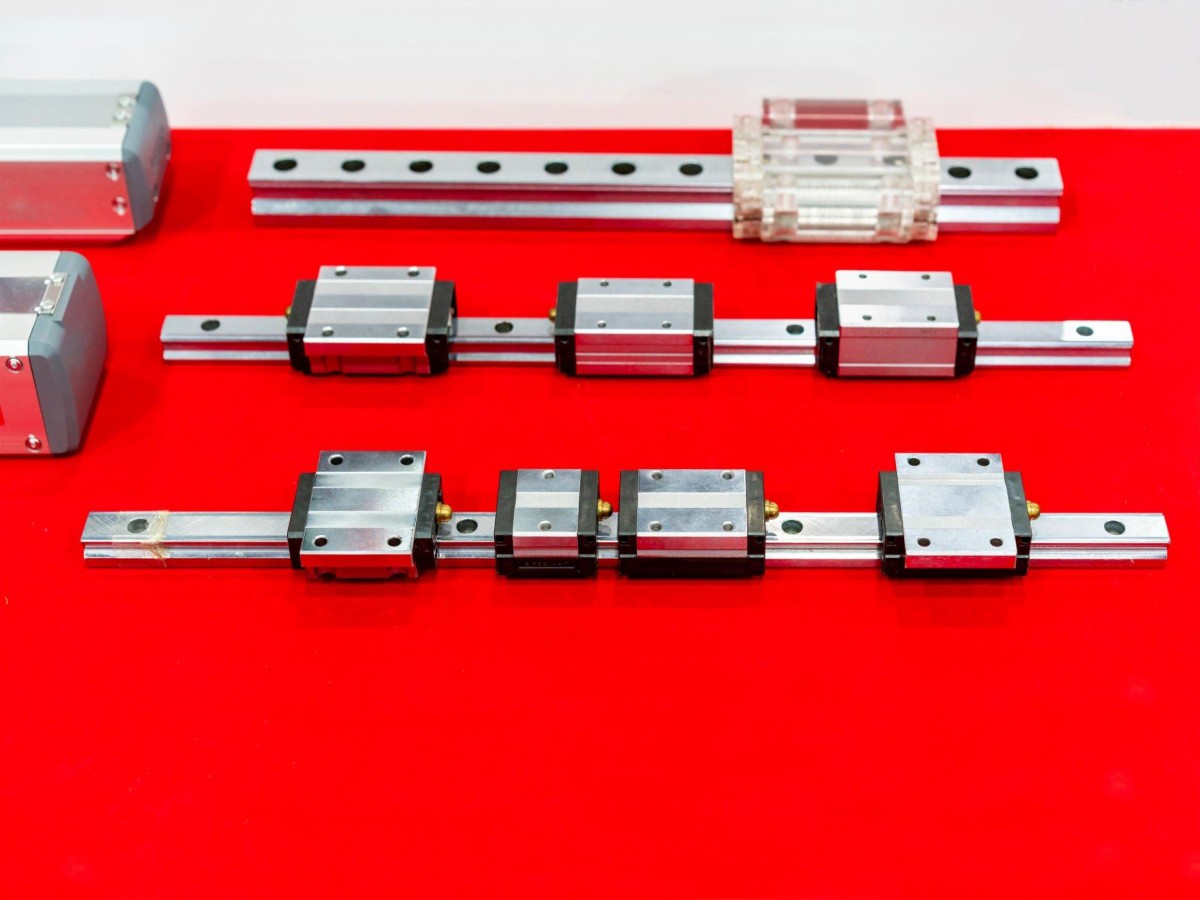

A linear guide rail system is a mechanical component that is used to guide and support linear motion in various types of machinery and equipment. It consists of a rail and a carriage that contains rolling elements such as balls or rollers. The carriage moves along the rail, providing smooth and precise linear motion.

Benefits of Linear Guide Rail Systems

Linear guide rail systems offer numerous advantages over other types of linear motion systems. Some of the key benefits include:

- High precision: Linear guide rail systems are designed to provide exceptional accuracy and repeatability, making them ideal for applications that require precise positioning.

- Smooth motion: The rolling elements in the carriage enable smooth and frictionless motion, minimizing wear and tear and ensuring long-term reliability.

- High load capacity: Linear guide rail systems can handle heavy loads while maintaining stability and precision, making them suitable for demanding industrial applications.

- Low maintenance: These systems are designed to require minimal maintenance, reducing downtime and improving overall operational efficiency.

- Easy installation: Linear guide rail systems are relatively easy to install, allowing for quick and hassle-free setup.

Choosing the Right Linear Guide Rail System

With a wide range of options available in the market, selecting the most suitable linear guide rail system can be a daunting task. Here are some factors to consider:

- Load capacity: Determine the maximum load that the system needs to support. Consider both static and dynamic loads to ensure the system can handle the required weight.

- Travel length: Measure the distance that the carriage needs to travel along the rail. This will help determine the appropriate rail length.

- Accuracy requirements: Assess the level of precision required for your application. Consider factors such as backlash, repeatability, and positional accuracy.

- Environment: Consider the operating conditions such as temperature, humidity, and exposure to dust or contaminants. Choose a system that is suitable for the specific environment.

- Budget: Determine your budget and look for a linear guide rail system that offers the best combination of performance and affordability.

Popular Applications of Linear Guide Rail Systems

Linear guide rail systems are widely used in various industries and applications. Some common examples include:

- CNC machines: Linear guide rail systems are extensively used in CNC machines to provide precise and smooth linear motion for cutting, milling, and drilling operations.

- Industrial automation: These systems are used in automated manufacturing processes to ensure accurate positioning and movement of robotic arms, conveyors, and other equipment.

- Medical equipment: Linear guide rail systems are employed in medical devices such as MRI machines, X-ray scanners, and surgical robots to facilitate precise and controlled movement.

- Printing and packaging: Linear guide rail systems are utilized in printing presses and packaging machines to enable precise and consistent movement of printing heads, packaging materials, and other components.

- Transportation: Linear guide rail systems are used in various transportation systems, including trains and trams, to ensure smooth and stable movement along tracks.

Conclusion

Choosing the right linear guide rail system is crucial for the success of your industrial or commercial application. Consider factors such as load capacity, travel length, accuracy requirements, environment, and budget to make an informed decision. By selecting the most suitable system, you can enhance the performance, reliability, and efficiency of your operations.