Introduction:

linear guide rails are an essential component in various industries and applications where smooth and precise linear motion is required. These rails are designed to provide support and guidance to moving parts, ensuring smooth and accurate movement along a specified path. In this article, we will explore the different aspects and benefits of linear guide rails, their applications, and why they are a crucial component in many industries.

The Basics of Linear Guide Rails

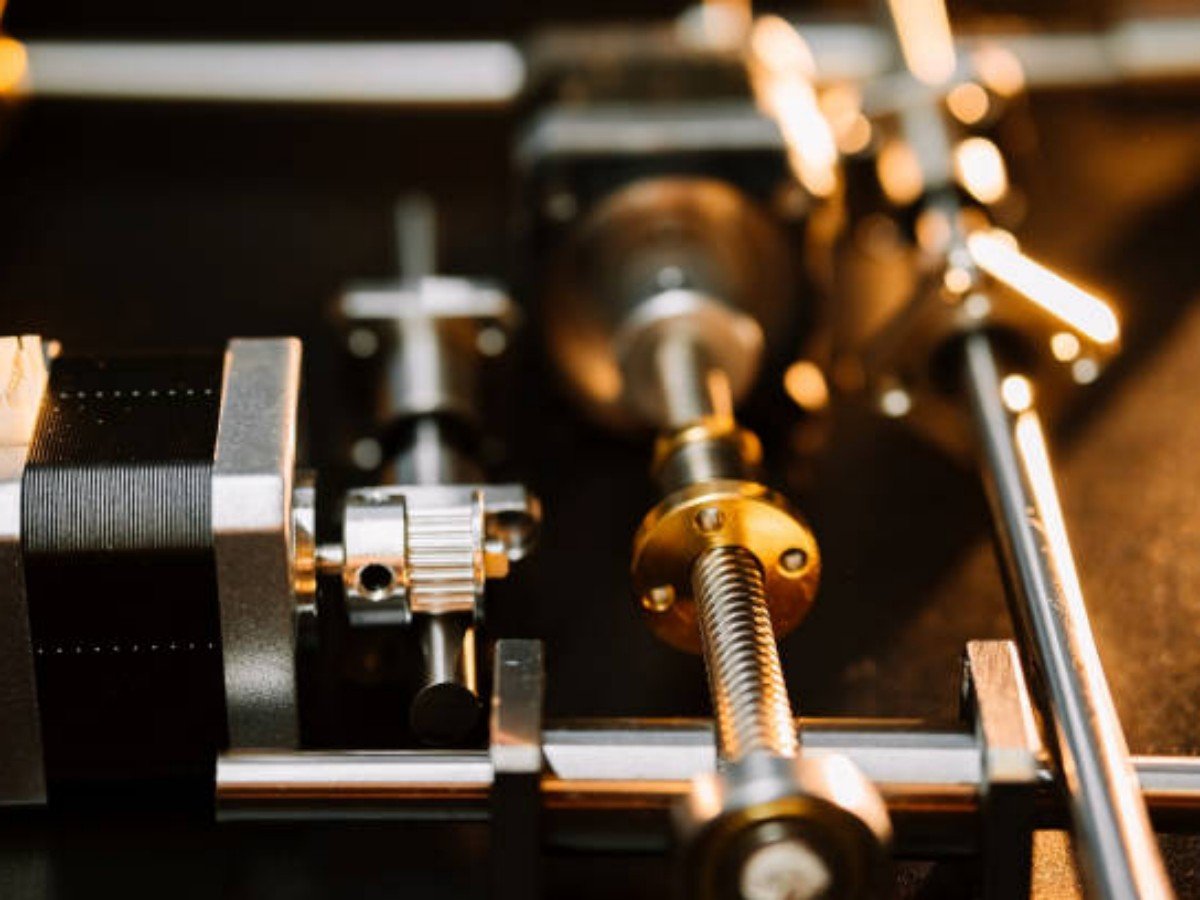

Linear guide rails, also known as linear motion guides, are mechanical systems that facilitate linear motion in machines and equipment. They consist of a rail and a carriage, where the carriage moves along the rail using rolling elements such as balls or rollers. The rolling elements minimize friction, enabling smooth and precise movement.

The Importance of Precision

Precision is of utmost importance in various industries, such as manufacturing, automation, and robotics. Linear guide rails play a crucial role in achieving this precision. By minimizing friction and providing support, these rails ensure that moving parts maintain accurate alignment and move smoothly along a predefined path. This precision is essential for achieving high-quality results, reducing errors, and increasing productivity.

Applications of Linear Guide Rails

Linear guide rails find applications in a wide range of industries and equipment. Some common applications include:

- Machine tools: Linear guide rails are integral components in machine tools such as CNC milling machines, lathes, and grinders. They enable precise movement of the cutting tools, ensuring accurate machining operations.

- Automation systems: Linear guide rails are used in various automated systems, including pick-and-place robots, assembly lines, and packaging equipment. They enable smooth and precise movement of components, enhancing overall system efficiency.

- Medical equipment: Linear guide rails are essential in medical equipment such as surgical robots, imaging systems, and diagnostic devices. They ensure precise movement and positioning, enabling accurate medical procedures and diagnosis.

- Transportation: Linear guide rails are used in transportation systems, including trains, trams, and conveyor systems. They facilitate smooth and reliable movement of vehicles and cargo.

The Benefits of Linear Guide Rails

Linear guide rails offer several benefits that make them an ideal choice for many applications:

- Precision: As mentioned earlier, linear guide rails provide exceptional precision, ensuring accurate and repeatable linear motion.

- Smooth operation: The rolling elements in linear guide rails minimize friction, resulting in smooth and quiet operation.

- High load capacity: Linear guide rails can handle significant loads, making them suitable for heavy-duty applications.

- Durability: Linear guide rails are designed to withstand rigorous operating conditions, ensuring long-lasting performance.

- Easy installation and maintenance: Linear guide rails are relatively easy to install and maintain, reducing downtime and enhancing productivity.

Choosing the Right Linear Guide Rail

When selecting a linear guide rail for a specific application, several factors should be considered:

- Load capacity: Determine the maximum load the rail needs to support to ensure optimal performance.

- Travel length: Consider the required travel length of the carriage along the rail.

- Accuracy requirements: Evaluate the precision and accuracy needed for the application to select the appropriate rail type.

- Environmental conditions: Assess the operating environment, including temperature, humidity, and exposure to dust or chemicals, to choose a rail with suitable protection.

- Budget: Consider the cost-effectiveness of the rail, balancing performance and budget constraints.

Maintenance and Lubrication

Proper maintenance and lubrication are crucial for ensuring the optimal performance and longevity of linear guide rails. Regular inspection, cleaning, and lubrication of the rails and carriages help prevent wear and reduce friction. Follow the manufacturer's recommendations for lubrication intervals and use appropriate lubricants to ensure smooth operation.

Conclusion

Linear guide rails are indispensable components in various industries, offering precision, smooth operation, and high load capacity. Their applications range from machine tools to automation systems and medical equipment. By choosing the right linear guide rail and ensuring proper maintenance, industries can achieve optimal performance, minimize errors, and enhance productivity.