Introduction

In the realm of precision motion control, aluminium linear guide rails have emerged as a game-changer. These versatile components play a crucial role in ensuring smooth and accurate linear motion in a wide range of applications. From industrial machinery to robotics, CNC machines to medical equipment, the advantages of aluminium guide rails are undeniable. Let's delve into the fascinating world of aluminium linear guide rails and unlock the potential for precision and efficiency.

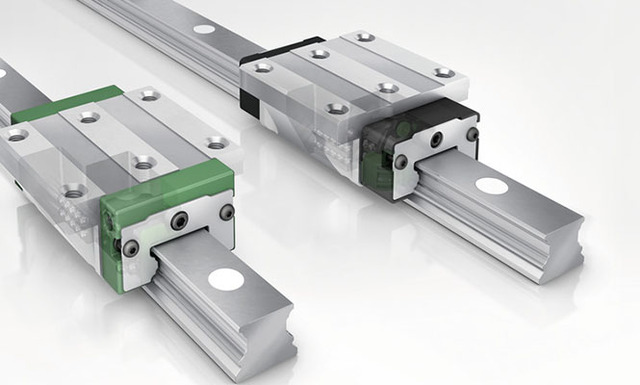

Advantages of Aluminium Linear Guide Rail

Aluminium linear guide rails possess several remarkable advantages that make them stand out in the world of motion control. Their lightweight yet durable construction provides the perfect balance between strength and maneuverability. Aluminium's natural corrosion resistance ensures longevity, even in demanding environments. Additionally, these guide rails exhibit high load-bearing capacity, low friction for seamless operation, and enhanced precision and accuracy, making them indispensable in applications that demand optimal performance.

Types of Aluminium Linear Guide Rail

There are different types of aluminium linear guide rails available to cater to specific needs. Standard profile guide rails are the most commonly used, offering versatile applications across various industries. Miniature aluminium guide rails, on the other hand, are designed for limited-space applications and intricate motion requirements. For heavy-duty applications, high-capacity aluminium guide rails provide robust support and stability, capable of handling substantial loads with precision.

Applications of Aluminium Linear Guide Rail

The applications of aluminium linear guide rails span across diverse industries. In industrial machinery and automation, these guide rails ensure precise and reliable movement for increased productivity. Robotics and assembly lines benefit from the smooth and accurate motion provided by aluminium guide rails, facilitating efficient operations. CNC machines and machining centers rely on the precision of these guide rails for flawless performance. In the realm of additive manufacturing and laser cutting, aluminium guide rails maintain stability and accuracy. Medical equipment and laboratory instruments also benefit from the precision and reliability offered by aluminium guide rails, ensuring optimal functionality.

Installation and Maintenance of Aluminium Linear Guide Rail

Proper installation and maintenance are vital for the optimal performance and longevity of aluminium linear guide rails. Careful mounting and alignment procedures ensure the rails function seamlessly. Regular lubrication and cleaning routines prevent friction and ensure smooth operation. Periodic inspections help identify any issues early on, allowing for timely maintenance and preventing potential problems that could affect performance.

Conclusion

Aluminium linear guide rails have revolutionized precision motion control, offering lightweight, durable, and high-performance solutions. Their advantages, including lightweight construction, corrosion resistance, high load-bearing capacity, low friction, and enhanced precision, make them indispensable in various industries. By choosing the right type of aluminium guide rail and following proper maintenance practices, businesses can unlock a world of precision and efficiency in their linear motion systems.

For more information, please contact us at once.

Contact information:0510-87609813

Mail:[email protected]

Telephone:+86-15900471118

Address:Room J4582, 1st Floor, No. 5358, Huyi Road, Jiading District, Shanghai