What are Linear Ball Guides?

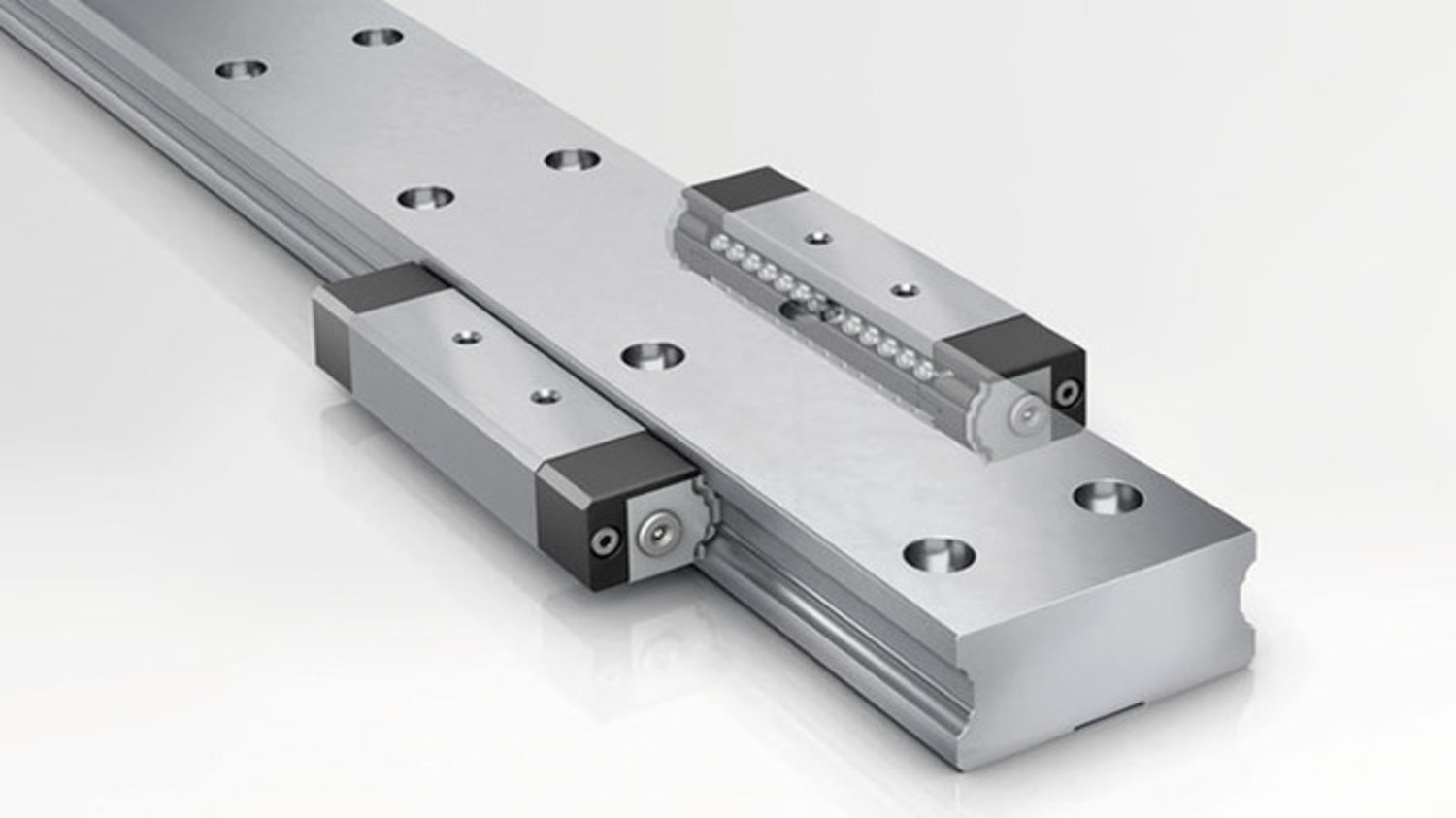

Linear ball guides are motion control components that are commonly used in various industrial and automation applications. They consist of a rail with recirculating balls or rollers that glide along the rail, providing smooth and precise linear motion.

How do Linear Ball Guides Work?

Linear ball guides work by reducing friction and eliminating stick-slip motion in a linear motion system. The recirculating balls or rollers in the guide carriage move smoothly along the rail, ensuring high accuracy and repeatability in positioning applications.

Advantages of Linear Ball Guides

Linear ball guides offer several advantages, including high precision, low friction, high load capacity, and long service life. They are also relatively easy to install and maintain, making them a popular choice for many industrial applications.

Applications of Linear Ball Guides

Linear ball guides are used in a wide range of applications, including CNC machines, robotics, semiconductor equipment, packaging machinery, and medical devices. They are ideal for any application that requires precise linear motion control.

Types of Linear Ball Guides

There are several types of linear ball guides available, including standard linear ball guides, miniature linear ball guides, and heavy-duty linear ball guides. Each type is designed to meet specific application requirements and performance criteria.

Choosing the Right Linear Ball Guide

When selecting a linear ball guide for your application, it is important to consider factors such as load capacity, speed, precision, and environmental conditions. Consulting with a knowledgeable supplier can help ensure that you choose the right guide for your needs.

Installation and Maintenance of Linear Ball Guides

Proper installation and maintenance are essential for the optimal performance and longevity of linear ball guides. Regular cleaning, lubrication, and inspection can help prevent wear and damage, ensuring smooth operation of the linear motion system.

Common Issues with Linear Ball Guides

Some common issues that may arise with linear ball guides include contamination, misalignment, and excessive wear. These issues can affect the performance of the system and should be addressed promptly to prevent further damage.

Future Trends in Linear Ball Guides

Advancements in materials, design, and manufacturing technology are driving innovation in linear ball guides. Future trends in the industry may include higher precision, lower friction, and increased load capacity to meet the evolving demands of automation and motion control.

Conclusion

Linear ball guides are essential components in a wide range of industrial and automation applications, providing smooth and precise linear motion control. By understanding their operation, advantages, applications, and maintenance requirements, you can make informed decisions when selecting and using linear ball guides in your projects.